home touch steamer instruction manual

Product Overview

The Home Touch Steamer is a versatile garment steamer designed for safe, efficient fabric care. It features quick heat-up, an integrated hanger, and a Safe Touch hose for comfortable use.

The Home Touch Steamer is a high-quality garment steamer designed for efficient fabric care. Available in models like IBPS200-C and PS-200, it offers quick heat-up in 45 seconds, an integrated garment hanger, and a Safe Touch hose for safe handling. With a water tank capacity providing up to 40 minutes of continuous steaming, it’s perfect for household use, ensuring smooth and wrinkle-free fabrics effortlessly.

1.2. Key Features of the Home Touch Steamer

The Home Touch Steamer stands out with its advanced features, including a fast 45-second heat-up time, an integrated garment hanger, and a telescoping design for compact storage. It also includes a 5-foot flexible hose with a Safe Touch cover for safe handling. The easy-fill water tank provides up to 40 minutes of continuous steaming, making it ideal for various fabrics and household needs. Additionally, it comes with a brush attachment for versatile cleaning tasks.

1.3. Compatible Models (PS-200, PS-251, IBPS200-C)

The Home Touch Steamer is available in three models: PS-200, PS-251, and IBPS200-C. The PS-200 is a compact, user-friendly option, while the PS-251 offers deluxe features for enhanced performance. The IBPS200-C is designed for commercial use, providing robust steam output for heavy-duty applications. All models share core functionalities, ensuring consistent performance across the range. Each model is tailored to meet specific user needs, whether for home, deluxe, or commercial use.

Safety Precautions

Always read the manual before use to avoid accidents. Keep the steamer away from children and pets. Never touch hot surfaces or direct steam at living beings.

2.1. General Safety Guidelines

Before using the Home Touch Steamer, ensure the power supply matches the specified 120V AC. Avoid using chemicals or substances other than tap water. Keep children and pets away. Never direct steam at people, animals, or plants. Do not touch hot surfaces or the upper part of the steamer during operation. Follow all instructions carefully to ensure safe and effective use.

2.2. Avoiding Burns and Accidents

To prevent burns, avoid touching hot surfaces like the steam nozzle or upper body of the steamer during operation. Keep children and pets away from the device. Never direct steam at people, animals, or plants, as it can cause injury. Use the Safe Touch hose for added protection and ensure the steamer is placed on a stable surface to avoid tipping. Always monitor its use to prevent accidents.

2.3. Warnings for Use Around People, Animals, and Plants

Keep the steamer away from children and pets to prevent accidental burns. Never direct steam at people, animals, or plants, as it may cause injury or damage. Ensure the device is placed on a stable surface to avoid tipping. Always maintain a safe distance from living organisms while operating the steamer to prevent harm.

Technical Specifications

The Home Touch Steamer operates on 120V AC power, producing continuous steam for up to 40 minutes. It features a 5-foot flexible hose and quick 45-second heat-up time for efficient fabric steaming.

3.1. Power Supply Requirements

The Home Touch Steamer requires a 120V AC power supply to function properly. Ensure the appliance is plugged into a grounded electrical outlet to avoid damage or electrical hazards. Using a different voltage may result in malfunction or safety risks. Always follow the power specifications outlined in the manual to maintain optimal performance and safety during operation.

3.2. Steam Output and Heat-Up Time

The Home Touch Steamer emits steam in just 45 seconds after turning it on, ensuring quick and efficient fabric care. It delivers continuous steam output for up to 40 minutes, making it ideal for multiple garments or extended use. The steamer is designed to maintain consistent steam flow, ensuring optimal results for various fabrics.

3.3. Water Tank Capacity and Continuous Steaming Time

The Home Touch Steamer features an easy-fill water tank that provides up to 40 minutes of continuous steaming. This capacity ensures efficient use for multiple garments or extended sessions. The tank is designed for convenience, allowing users to refill water without interrupting the steaming process. This makes it ideal for both home and professional settings, offering consistent performance for various fabric care needs.

Operating Instructions

Plug the steamer into a 120V AC outlet, turn the switch on, and wait 45 seconds for steam. Use the reset button if needed for troubleshooting.

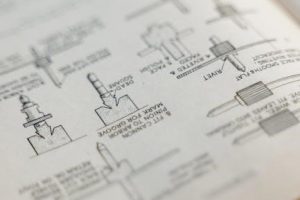

4.1. Assembly and Initial Setup

Unpack the steamer, brush attachment, and measuring cup. Attach the steam hose to the main unit and hangar. Plug into a 120V AC outlet. Fill the water tank with tap water using the measuring cup. Ensure all connections are secure. Check for leaks. Turn on the power and allow the steamer to heat up before first use.

4.2. First-Time Use and Preparation

Plug the steamer into a 120V AC outlet. Turn on the switch; the indicator light will illuminate. Allow 45 seconds for heat-up. Steam should emit from the nozzle. Before first use, ensure all parts are securely connected. Check for leaks and proper water level. Use the measuring cup to fill the tank with tap water. Avoid overfilling. Let the steamer run for a few minutes to ensure proper function.

4.3. Daily Operation and Maintenance Tips

For optimal performance, ensure the water tank is filled with tap water only, avoiding chemicals. After each use, empty the tank and dry it to prevent mineral buildup. Regularly clean the steam nozzle to maintain flow. Store the steamer upright in a cool, dry place. Descale every 2-3 months if using hard water. Always check for damage before each use and ensure all parts are securely connected.

4.4. Reset Button and Troubleshooting

The reset button (Fig. 9) is designed to restore the steamer to its default settings if it malfunctions; Press and hold it for 5 seconds to reset. Common issues include no steam output, often due to low water levels or a blocked nozzle. Check the power supply, ensure the water tank is filled, and clean the nozzle regularly. If issues persist, unplug the device, allow it to cool, and restart. Refer to the manual for detailed troubleshooting guides.

Common Issues and Solutions

The Home Touch Steamer may experience no steam output due to low water levels or blockages. Ensure the water tank is filled and the nozzle is clean. The black button function aids in troubleshooting by resetting the device if it malfunctions, restoring normal operation quickly and efficiently.

5.1. No Steam Output: Possible Causes and Fixes

If the Home Touch Steamer stops producing steam, check for common issues like low water levels, blockages, or mineral buildup. Ensure the water tank is filled and the nozzle is clear. Descale the unit regularly to prevent lime buildup. Avoid using chemicals or substances other than tap water, as this can damage the steamer. If issues persist, reset the device using the black button or consult the troubleshooting guide for further assistance.

5.2. Understanding the Black Button Function

The black button on the Home Touch Steamer serves as a reset feature, helping to restore normal operation when issues arise. Pressing it can resolve problems like no steam output or malfunctioning components. It also aids in clearing internal blockages or errors. Use this button cautiously, as it resets all settings. Refer to the manual for specific scenarios when to use this function to ensure optimal performance and troubleshoot effectively.

Additional Features and Accessories

The Home Touch Steamer comes with a brush attachment for tough stains and a measuring cup for precise water filling, enhancing its functionality and ease of use.

6.1. Brush Attachment and Its Uses

The Home Touch Steamer includes a brush attachment designed for tackling tough stains and delicate fabrics. It helps remove dirt and odors effectively while preserving fabric integrity. Use it for upholstery, curtains, or heavy-duty cleaning. The brush attachment enhances the steamer’s versatility, making it ideal for various household and garment care needs; It ensures a deeper clean without damaging materials, providing a gentle yet thorough cleaning experience.

6.2. Measuring Cup and Water Guidelines

The measuring cup ensures accurate water levels for optimal steaming performance. Use only tap water, as chemicals or additives can damage the steamer. Fill the water tank up to the maximum level indicated to avoid operational issues. For hard water areas, consider using distilled water to prevent limescale buildup. Always allow the steamer to cool before refilling to ensure safety and longevity of the device.

Warranty Information

The Home Touch Steamer comes with a comprehensive warranty covering manufacturing defects for a specified period. Register your product for extended support and easy claim processing online.

7.1. Coverage and Duration

The Home Touch Steamer warranty covers manufacturing defects in materials and workmanship for a period of one year from the date of purchase. Registration is required to activate the warranty. Damages caused by misuse or improper maintenance are not covered. Proof of purchase and adherence to the instruction manual are necessary for valid claims;

7.2. Registration and Claim Process

To activate the warranty, register your Home Touch Steamer on the manufacturer’s website with proof of purchase. For claims, contact Home Touch customer support, providing the product serial number, purchase date, and a detailed description of the issue. Claims must comply with warranty terms and conditions outlined in the manual. Ensure all documentation is complete to facilitate a smooth process.

The Home Touch Steamer offers efficient fabric care with advanced features and safety measures. Follow the manual for optimal performance and longevity of your steamer.

8.1. Final Tips for Optimal Use

For the best results, always check fabric labels before steaming and use distilled water to prevent mineral buildup. Regularly clean the steam nozzle and descale the unit to maintain performance. Store the steamer upright and empty the water tank after use to avoid bacterial growth. Use the brush attachment for tougher fabrics and ensure the garment is slightly damp for effective steaming. Follow these tips to extend the life of your Home Touch Steamer and achieve professional-quality results at home.

8.2. Importance of Following the Instruction Manual

Following the instruction manual ensures safe and effective use of the Home Touch Steamer. It helps prevent damage to fabrics, avoids appliance malfunction, and guarantees optimal performance. By adhering to guidelines, users can maintain warranty coverage and extend the product’s lifespan. Always read the manual before first use to understand safety precautions, proper assembly, and maintenance tips. This ensures a seamless and hazard-free steaming experience.

About the Brand

Home Touch is a trusted brand committed to delivering high-quality, innovative products like the PerfectSteam series, ensuring reliability and customer satisfaction in household appliances.

9.1. Home Touch and Its Commitment to Quality

Home Touch is dedicated to providing premium products that combine innovation and durability. Their commitment to quality ensures that every device, like the PerfectSteam series, meets high standards, offering reliability and efficiency. By focusing on user safety and satisfaction, Home Touch has established itself as a trusted name in household appliances, delivering exceptional performance and value.

9.2. Other Products in the PerfectSteam Series

Home Touch offers an array of products in the PerfectSteam series, each designed to meet diverse steaming needs. From compact models like the PS-200 to advanced versions such as the IBPS200-C, these steamers deliver efficient performance. Accessories like brush attachments and measuring cups enhance functionality, making the series a comprehensive solution for fabric care and beyond, ensuring versatility and convenience for users.